Wacker Neuson's smallest reversible vibratory plate, the WPU1550, is a powerful professional for compacting asphalt, interlocking paving stones, and mixed soils in the tightest of spaces. Its robust construction makes it ideal for continuous professional use in gardening and landscaping, as well as road construction. It is particularly suitable for compacting gravelly sand beds on sidewalks, roads, and parking lots. Thanks to the integrated, extremely stable transport roller, the WPU1550 can be moved effortlessly and effortlessly to the desired location on the construction site – even on hot asphalt.

Maximum compaction in the tightest spaces.

These lightweight, reversible vibratory plates offer maximum compaction in the tightest spaces and are among the powerful all-rounders for paving work, gardening and landscaping, as well as for maintenance work on roads, paths, and parking lots. Like all vibratory plates in the 25–37 kN class from Wacker Neuson, they are equipped with a robust, integrated wheel set that enables mobility on the construction site that is unique in the market. Thanks to their compact design and high maneuverability, they are particularly well-suited for compacting ditches, sidewalks, and other confined areas. Well-thought-out details make them the ideal compaction machine for continuous professional use.

Unbeatable on any surface

The medium-duty reversible vibratory plates, weighing 300 to 600 kg, are unbeatable on any surface. With their powerful compaction force and fast forward and reverse motion, they enable high productivity and are ideal for construction sites with high demands on the equipment's performance. They also impress with their durability and high level of user-friendliness. Typical applications include the compaction of frost and base layers in road, path, and parking lot construction, as well as the backfilling of buildings. With a frequency of 69 Hz, these vibratory plates are universally applicable and reliably compact even medium to heavy interlocking paving stones.

Powerful and flexible on all surfaces.

The forward-moving DPS vibratory plate is a powerful machine for soil and asphalt compaction and is ideal for processing surface and base courses. It was specially developed for tough, continuous use on construction sites. Its robustness is enhanced by a diesel engine with large power reserves, a wear-resistant base plate made of spheroidal graphite cast iron (GJS 700), and maintenance-free and extremely durable exciter bearings. The ergonomically positioned throttle lever and vibration-damped guide handle ensure high operating comfort.

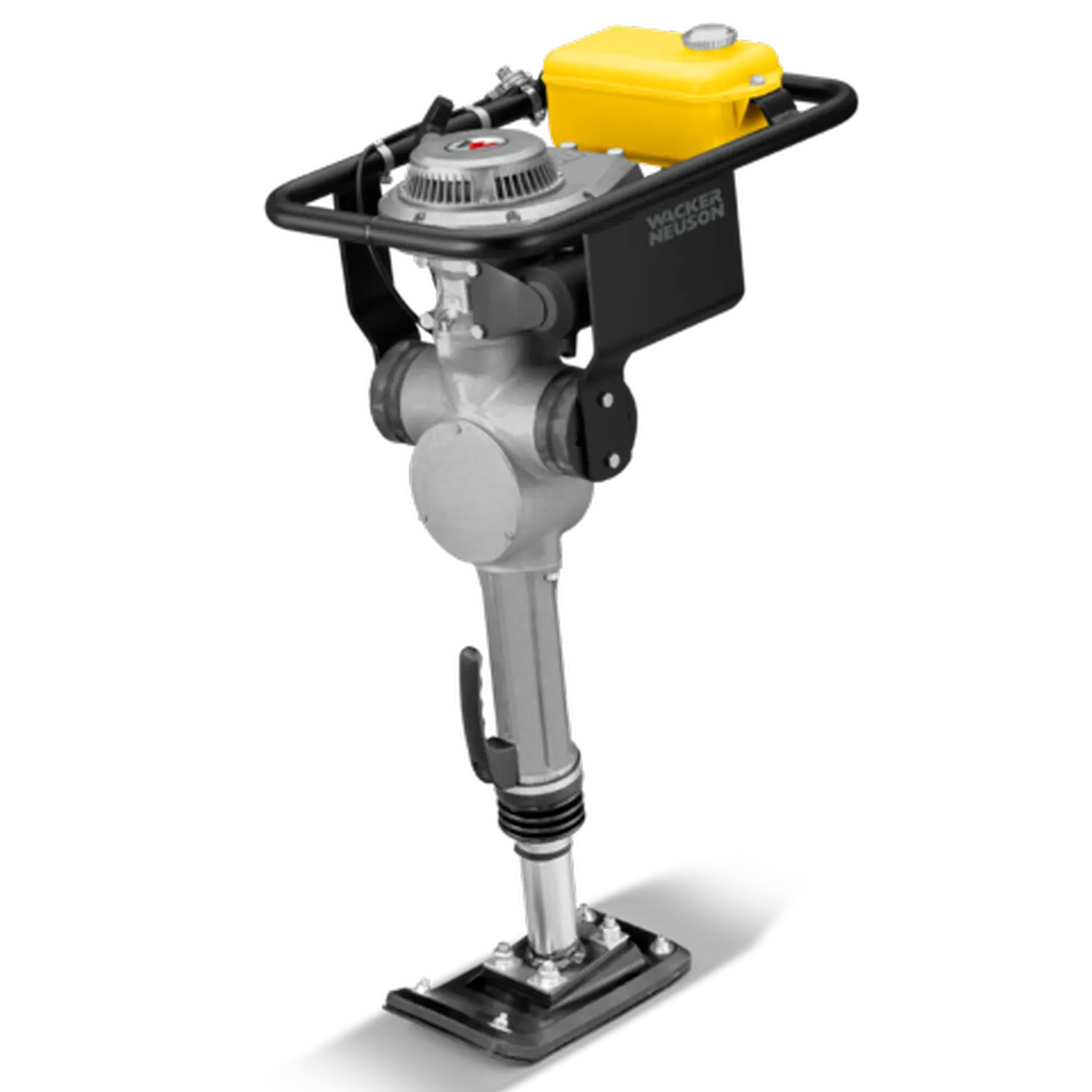

Complete all conventional rammer work emission-free.

With the battery-powered rammer, the operator works completely emission-free. It's not only a great advantage for soil compaction in trenches and urban areas, but also reduces the strain on the operator and the environment on every construction site. One battery charge is sufficient to complete all the work required for an average workday. The battery can be replaced in just a few steps without tools and can be used for numerous other Wacker Neuson construction machines.

The special rammer for pipe joints.

The BS30 is the special rammer for the professional compaction of pipe joints in trenches. Thanks to its light weight, compact dimensions, and the ability to deliver full power even when tilted, the BS30 two-stroke rammer is the only choice for such tasks. It is equipped with the WM80 engine, developed in-house by Wacker Neuson.

Top performance and easy operation.

If you're looking for a powerful and reliable four-stroke rammer, you've come to the right place. Our four-stroke rammers impress with their high efficiency and quality. They feature a long stroke, a high rammer frequency, and powerful impact energy, enabling optimal compaction. They're also easy to operate, robust, and low-maintenance. The throttle lever with integrated fuel tap simplifies operation, and a particularly efficient air filter protects the engine from dirt and ensures consistent, reliable performance.

Top performance when cutting asphalt and concrete.

Wacker Neuson's gasoline-powered floor saws are distinguished above all by their first-class cutting performance. All models are up to 20% faster than comparable machines, meaning the BFS series offers the highest cutting speed with smooth operation. This is due to the efficient coordination of the torque transmitted to the diamond blade and the center of gravity located above the cutting shaft. And all this while remaining lightweight, as the BFS series is the lightest machine in its class.

The entry-level model for demolition.

The BH55 petrol demolition hammer from Wacker Neuson is the ideal entry-level model among demolition hammers. It is lighter and more compact than other petrol hammers and impresses with its handy size, ease of operation, and excellent power-to-weight ratio.